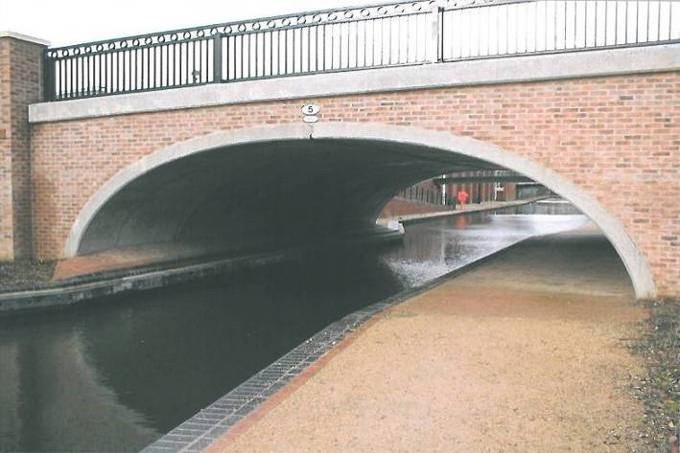

Geoquest’s precast arch system: Engineered solutions for heavy-load applications

Geoquest’s precast arch is a proven, durable, and versatile structural solution for civil, industrial, and military infrastructure projects. A trusted choice among engineers worldwide, these precast concrete arches are designed for a wide range of applications, including:

- Roadway and railway underpasses, overpasses, and tunnel structures

- Explosives and munitions storage facilities for defense and heavy industry

- Conveyor tunnels, utility corridors, and escape routes in industrial sites

- Pedestrian walkways and commercial underpasses

- Rockfall protection shelters and mountain-side galleries

- Wildlife crossings and pedestrian pathways in natural areas

Engineered for Performance and Simplicity

Geoquest’s precast arch system combines advanced structural engineering with ease of installation. Designed using Finite element model analysis design (FEM), each arch is optimised to handle high fills, dynamic live loads, and complex loading scenarios – both during installation and throughout its service life.

By accurately calculating the ideal arch geometry, we minimise tensile stress and maximise durability. This leads to slender, reinforced concrete sections that ensure long-term performance, safety, and cost-effectiveness.

Precision Manufacturing for Quality and Consistency

Each precast arch is manufactured using flexible, high-precision formwork under strict quality control standards. This ensures that every element meets exact geometric and structural specifications.

Geoquest also supplies complementary precast components such as footings, wing walls, copings, barriers, slip joints, and spandrels – delivering a comprehensive structural package for fast and seamless construction.

Fast, efficient, and predictable installation

Geoquest’s precast arch system is designed for rapid deployment with minimal site disruption. With a narrow construction footprint and no need for extensive formwork or scaffolding, installation is fast and efficient. Crews can typically install 10–20 meters of arch per shift using a single crane, with even faster rates achievable using two cranes.

Installation can be completed over active railways, roads, and waterways without interrupting daily operations – making it ideal for time-sensitive infrastructure projects.

Installation typically includes:

- Preparing keyway foundations

- Receiving and staging arch segments

- Placing segments by crane(s)

- Grouting segments into the foundation

- Pouring a crown beam or stitch joint

- Waterproofing and sealing joints

- Backfilling according to engineering guidelines

Speak to our team about your next project

Engineering expertise and 120 years or more of service life

Geoquest offers unrivalled engineering expertise to provide you with the best design and supply package, coupled to commercial excellence that will make your next road development project a success.

Guaranteeing long-term life duration and minimum necessity for maintenance of the infrastructure is of outmost importance, and our designs are optimised based on the service life that is required.